Engine overhaul procedure The following description applies directly to a large number of Craftsman mowers using Tecumseh engines (most do). However, with minor modifications, it is also applicable to most other mowers using stroke engines. Mechanically, stroke engines are very similar.

Rebuilding an engine is a big job, but planning smartly for a successful rebuild project can help eliminate the possibility of costly mistakes, saving you time, energy, and frustration. General engine overhaul procedures. This is part of the overhaul.

An overhauled engine is one that has been remove disassemble cleane inspecte repaired as necessary and tested using factory service manual approved procedures. The procedure generally involves honing, new piston rings, bearings, gaskets and oil seals. Overhauling generator can major or. The exact procedure will vary according to the engine model being repaired.

For information on how to perform most operations liste refer to the page number or operation. Be careful to locate the instructions covering the specific model being repaired. Our service advisor will review the “Power-by-Victor” engine overhaul or upgrade series with you and make recommendations on what series of overhaul and options would best suit your aircraft application needs. Most people have heard of an engine rebuild but not as many really know what a rebuilt engine really is or what is done when an engine is rebuilt. We also have on our panel engineers from the engine manufacturers of British and German origin.

Our marine diesel engine overhaul and repair services include overhaul , maintenance, repairs for low and medium-speed marine and industrial diesel engines and turbochargers, Governor as well as spare parts supply. Check back often for updates. A top overhaul is a little misleading, because it is really an engine repair procedure and not a real overhaul as described earlier. Usually at this time, the accessories require no attention other than that normally required during ordinary maintenance functions.

A diesel engine is an internal ignition engine , which utilizes heat to burn the fuel. It has the highest thermal efficiency of any regular engine because of its high compression ratio. The average service life of a diesel engine is usually about years. It then needs to be rebuilt or replaced from. How do I properly break in an engine after a rebuild.

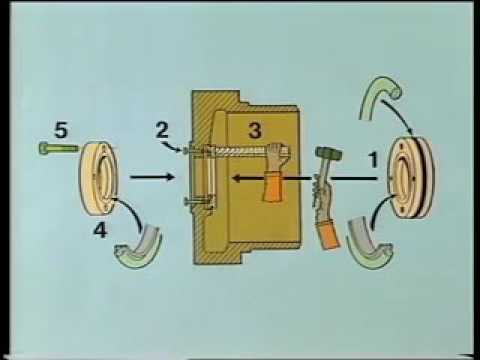

Piston ring breaking standard procedure involves how the engine is used for the first 5miles. Illustrations and procedures have been chosen to guide mechanic through engine overhaul process. Descriptions of processes of cleaning. Of course, this is a dangerous attitude. Lock off the engine staring mechanism.

Drain off the oil from both drain plugs. The engine was beyond the recommended time period for overhaul both in hours and calendar time. Remove the turbocharger air filter.

The engine had been barely passing the requirements for compression tests and had begun to have higher oil consumption. Reports of previous overhauls can prevent the same mistake from being made twice and may provide tips that can expedite the overhaul procedure. The maintenance files may also provide names of sources for parts and materials. Question about engine overhaul break-in procedures. I finally decided to do the break in procedure as per the performance motorcycle engine building shops which.

There are different ways of overhauling an engine. Most workshops do what is called an in-chassis rebuild. Oil Requirements for Turbocharged Engines – DO NOT USE MINERAL OIL IN LYCOMING TURBOCHARGED ENGINES.

As per Lycoming break-in instructions , the use of mineral oil is known to cause coking in the turbo(s). Penn Yan Aero recommends the use of AeroShell Straight Weight 100W Plus or 80W Plus Ashless Dispersant Oil. English dictionary definition of overhauling.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.